SITE LOGIN

-

REVIEWS

- Ski Gear

- Clothing

- Accessories

- Off-Season Gear

- Lifestyle

- Lodges and Accommodation

- Nutrition

- Manufacturers

- Destinations

- Training

- Gear of the Year

- Best New Summer Gear

-

Holiday Gift Guide

-

Holiday Gift Guide 2024

- Holiday Gift Guide 2024 Base Layers

- MSR Explore Revo Snowshoes

- Fieldsheer Backcountry Heated Jacket

- Fieldsheer Premium 2.0 Merino Heated Socks

- MEC Hut Booties and Slippers

- Arc’teryx Kopec GTX Shoe

- Arc’teryx Kragg Insulated Approach Shoes

- Gregory Verte 18 Backpack

- Grundens Deck-Boss Ankle Boot

- MEC Northern Light Vest

- Montec-Scope-Ski-Goggles

- Mountain Hardware Kor Airshell Hoody

- Mountain Hardware Kor Alloy Crew

- Arcade Atlas Belt

- Dynafit Ridge Dynastretch Jacket

- Shokz OpenRun Pro 2 headphones

- Buff Merino Move Multifunctional Neckwear

- Bootdoc Foot Warmer

- Cotopaxi Allpa 42L Travel Pack

- DPS LastBag

- DPS PHANTOM Glide At-Home Kit

- DPS Mission Quiver Roller

- Dragon Amped sunglasses

- Dragon DX3 Plus OTG photochromic goggle

- Fuse Lenses Anclote Flashback

- Garmin Fenix 8 Solar Sapphire Watch

- Gregory Alpaca Gear Tote 30

- Hotronic Boot Dryer

- MEC Aluminum Pot Set

- Gnara Go There Pants

- Grundens Shackleton 2.0 Duffel

- Jones Deeper 19L Backpack

- Le Bent Core Midweight Crew base layer

- Leatherman ARC

- Montane Nordes Hooded Softshell Jacket and Pants

- Helly Hansen Odin Everdown Hooded Jacket

- Helly Hansen Verglas Infinity Shell Jacket 2.0

- Montec Fawk Ski Jacket

- Pomoca Free Pro 2.0 Skins

- Rab Glaceon Pro Down Jacket

- Rab Khroma Converge GORE-TEX Ski Jacket & Pants

- Smith Squad MAG Goggles

- Stellar Guide Aerogel Hybrid Hood 2.0

- Stellar Ultralight Down Hood 2.0

- Arms of Andes Alpaca Half Zip & Wool Leggings

- Cotopaxi Allpa 70L Duffel Bag

- Giro Taggert Mips Helmet

- Loonr Hi Flyer Boots

- Paka Mountain Crew

- Roll Recovery SUPERPLUSH Classic Shoes

- Smartwool Smartloft Hooded Jacket and Pants

- Ortovox Switchback 32 Ski Touring Backpack

- Cotopaxi Allpa X 3L Hip Pack

- Giro Sagen Ski Goggle

- Icebreaker Ski+ Over the Calf Socks

- MEC-Fireside-Fleece-Snap-Pullover

- Montec Roast Mittens

- Mountain-Hardware-Sunblocker-Hoody

- MSR Titan Kettle 900 ml

- Tailgate-Industries-The Gondom-Goggle-Cover

- Wild Country Rope Tarp

- Bootdoc Race Merino PFI 50 Socks

- Remind Soles Destin Impact Insoles

- Kari Traa Rose Baselayer Half Zip Top and Pants

- Le Bent Midweight Quarter Zip

- Ombraz Dolomite Sunglasses

- Ortovox Fleece Rib Hoody

- Ortovox Merino Thermovent Base Layer

- Smartwool Intraknit Merino Tech Half Zip

- Suunto Wing Bone Conduction headphones

- Sweet Protection Adapter Mips Helmet

- Sweet Protection Connor Rig Reflect Goggles

- Zeal Optics Selkirk Glacier Glasses

- Norrona more flex1 Pants

- Norrona Octa Zip Hood

- Norrona Lyngen Alpha100 Zip Hood

- MEC Deluxe Pillow

- Holiday Gift Guide 2023

- Holiday Gift Guide 2022

- Holiday Gift Guide 2021

- Holiday Gift Guide 2020

- Holiday Gift Guide 2019

- Holiday Gift Guide 2018

- Holiday Gift Guide 2017

- Holiday Gift Guide 2016

-

Holiday Gift Guide 2024

- Pro Skier Interviews

- NEWS

- STORE

- ROUTES

- LODGING

-

VIDEOS

- 2022/23 Gear Reviews

- 2021/22 Gear Reviews

- 2020/21 Gear Reviews

- 2019/20 Gear Reviews

- 2018/19 Gear Reviews

- 2017/18 Gear Reviews

- 2016/17 Gear Reviews

- 2015/16 Gear Reviews

- 2014/15 Gear Reviews

- 2013/14 Gear Reviews

- 2012/13 Gear Reviews

- 2011/12 Gear Reviews

- 2020 Outdoor Retailer

- 2019 Outdoor Retailer

- 2018 Outdoor Retailer

- 2017 Outdoor Presscamp

- 2017 Outdoor Retailer

- 2016 Outdoor Presscamp

- 2016 Outdoor Retailer

- 2015 SIA Show

- 2014 Outdoor Retailer

- 2013 SIA Show

- 2012 Outdoor Retailer

- Tips and Tricks

- Backcountry Skiing

- SAFETY

- ABOUT

- REVIEWS

- NEWS

- STORE

- ROUTES

- LODGING

-

VIDEOS

- 2022/23 Gear Reviews

- 2021/22 Gear Reviews

- 2020/21 Gear Reviews

- 2019/20 Gear Reviews

- 2018/19 Gear Reviews

- 2017/18 Gear Reviews

- 2016/17 Gear Reviews

- 2015/16 Gear Reviews

- 2014/15 Gear Reviews

- 2013/14 Gear Reviews

- 2012/13 Gear Reviews

- 2011/12 Gear Reviews

- 2020 Outdoor Retailer

- 2019 Outdoor Retailer

- 2018 Outdoor Retailer

- 2017 Outdoor Presscamp

- 2017 Outdoor Retailer

- 2016 Outdoor Presscamp

- 2016 Outdoor Retailer

- 2015 SIA Show

- 2014 Outdoor Retailer

- 2013 SIA Show

- 2012 Outdoor Retailer

- Tips and Tricks

- Backcountry Skiing

- SAFETY

- ABOUT

TOP VIDEOS

- Home

- »

- REVIEWS

- »

- Manufacturers

- »

- Polygiene

Polygiene

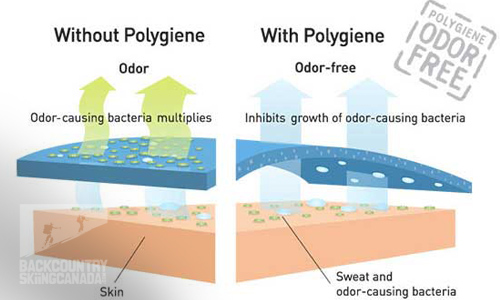

Polygiene Odour Control Technology is designed and produced from the company headquarters in Malmö, Sweden. Polygiene is bound and permanently integrated into synthetic sportswear to inhibit the growth of odour-causing bacteria. As many of us have experienced, the major downfall to synthetic clothing is the stinky smell that seems to persist in clothing over time, even after washing. Moreover, synthetic athletic wear typically needs to be washed after every use or two because of odour buildup. Polygiene seeks to remedy this problem while simultaneously reducing consumer environmental impact.

The company uses silver chloride, a naturally occurring salt, to prevent odour-causing bacteria and fungi from growing on synthetic clothing. This innovative approach seeks to restrict the growth of bacteria on the product as an alternative to blocking sweat glands with chemical compounds (deodorant) that are either harmful to the user or mostly ineffective. The Polygiene technology is only active on the clothing and does not transfer to the wearer, guarding the natural bacteria flora on the skin from damage.

Aside from assisting athletes to smell better, Polygiene also endeavours to help minimize the environmental impact of outdoor enthusiasts. The company’s tag line Wear More Wash Less addresses the fact that washing and drying clothing account for over half of an item’s ecological footprint. As water conservation becomes an increasingly necessary practice, Polygiene serves to encourage consumers to wash their clothing less by making it less compulsory.

- SHOW THE REST OF THE REVIEW / PHOTOS / VIDEOS

-

An additional benefit to washing clothing less often is that it increases the life-span of a product. The quick-drying qualities of most polyester and polypropylene materials means that it is easier and more convenient to air dry clothes, even in cold environments. The fact that the clothes or gear can be used longer also saves time by doing fewer loads of laundry and money by replacing garments less frequently.

In terms of the company’s environmental impact, Polygiene endeavours to be as ecologically neutral as possible. Polygiene is bluesign® approved, which ensures the sustainability of textile production. The silver is recycled from electronics waste, efficiently reusing a precious metal instead of sending it to the landfill. It is applied during the final stage of production, at the same time as other garment treatments, thereby eliminating the need for extra energy or water usage during the application process.Environmental Specs:

- Bluesign® approved

- On the Oeko-tek list (I-IV) of independently tested and certified products

- Registered under the EU Biocidal Product Regulation

- Meets the requirements of the EU’s chemicals legislation, REACH

- Approved by the US Environmental Protection Agency (EPA)

- Approved for use by ECO CIRCLE, a Japanese textile-recycling programAs the technology becomes more common, expect to see Polygiene applied to more than garments. It has been used on a variety of gear including helmets, footwear, wetsuits, bags, and protective equipment. The company has also developed an application process for surfaces to prevent the growth and transfer of bacteria and fungi in high-traffic areas and public places such as hospitals, hotels, public transit stations, public washrooms, and more.

Products tested:

- La Sportiva Hero Long Sleeve

- La Sportiva Apex T-Shirt

- La Sportiva Galaxy 2.0 Hoody

- La Sportiva Galaxy Pants

- Polygiene Performance Socks

- Dissent Semenuk Genuflex Compression Socks

- Athleta Pacifica UPF Tank

- Athleta Printed Endura Half Zip

- Patagonia Capilene Thermal Weight Zip Neck

The following interview was conducted with Christian von Uthmann, CEO of Polygiene, and has been edited for brevity and pertinence.

What sparked the inspiration to create Polygiene? What gave you the idea that silver chloride could be integrated into fabric to kill bacteria?

We started Polygiene within Perstorp, which is a specialty chemicals company in Sweden. We had a lot of requests from the sanitary industry to make toilet seats, which are more hygienic than the ones without Polygiene. This is how it all started back in 2000. The name Polygiene is the combination of two words, polymer and hygiene, into one.The products we were making were taken to all kinds of shows, and people started coming up to us saying that they were interested in introducing Polygiene to their own materials such as wood, metal, or textile. So that’s how we came to get involved in textiles in the beginning. And then later the Scandinavian brands came to us and said that they had been to the USA and learnt that if you can inhibit the growth of bacteria on the fabric, then it’s not going to smell as bad. We started partnering with the Scandinavian outdoor brands and then moved from there to Europe, and also to North America and Asia.

Has your focus shifted more toward the outdoor industry overall?

Yes, we’ve seen over the years that textile and sports and outdoors make up perhaps 85% of our business, but we still keep a good business going in healthcare which was instrumental in our development. We learned to be very efficient; for example, if you say you’ve killed those bacteria you have to do it. Secondly, you also learn to be very skin friendly and safe, and thirdly you really have to have your environmental story in place. All of those three parameters of core competency work very well in the sports and outdoor sector, but also in a wider context of the textile industry if you look at lifestyle and home textiles or interior decoration for example.The tag line Wear More Wash Less tells the consumer that they need to wash their product less often. Is there an optimal amount of usage before washing? How many times can a user expect to wear the garment before washing? A t-shirt, for example?

The answer depends on the individual, but a good example is of when I was in Norway ski touring. We went for one week and I used the same base layer, which was Polygiene treated of course, and I’m a fairly sweaty guy. Some people will go for longer. I’ve tested it a number of times and I’d wear the same shirt around my family without complaint for four or five days. The whole point is that if you’re not thinking about developing odor in your garments then you’re going to have more confidence and be able to focus more on what you’re doing whether it’s ski touring or running or training in the gym or yoga. The garment’s not going to smell bad, so you’ll have to wash it less often and you’re actually going to gain more time to spend with your friends or family or doing your favourite sports.In the outdoor market merino wool is often touted as the best antibacterial material available. How do the two materials compare?

First of all Polygiene is a treatment, so it can actually go on any fabric, and we’re not limited. We’ve got polyester, nylon, cotton, any blend you have can be treated. Second, wool is not antimicrobial in the sense that it’s killing bacteria, but it’s good in the sense that the bacteria is not going to grow as fast, which will slow the development of odor. This is important for socks for example, as the Polygiene is not only killing the bacteria, but also the fungi.It’s very personal; some people like wool and that’s great. A lot of people using wool have learned that you don’t have to stink or have a bad odor. Wool has potentially been good for Polygiene because it’s educated the consumer about not having to smell any longer.

I have been told many times that high-tech garments like waterproof, breathable rainwear need to be washed relatively frequently because sweat can damage and break down the materials. Is this a concern for Polygiene fabrics and its transferability into more products?

Yes, it can be applied to almost anything. In that case we might go directly to putting a coating on, as we’ve done in a couple of cases. For example, if you have a very light shell product used for mountain biking or running, you’re going to include the Polygiene with the outer treatment. The choice is to apply Polygiene to the garment itself or as a coating.How is Polygiene integrated into material? Is it always a coating?

In fact there are many different ways. Fabrics all receive some kind of treatment, either in a bath or in some kind of dye, and Polygiene can also be applied as a liquid in one of these baths together with other treatments. For footwear or helmets, where you have a molded product such as EVA foam in the footbed, then you go into the plastic and it’s a powder or emulsifier. This allows for a wide range of application possibilities.This makes sense, since you can’t actually see the silver chloride on the fabric and wouldn’t know it’s there.

Correct. We’ve worked a lot with the bicycle industries where they have a lot of very bright colours, white white or vibrant pink or very strong colours. This treatment process is a big advantage for Polygiene because it’s not going to change any of the esthetics, such as the colour, or the hand feel of the fabric. Moreover the colours are actually going to live longer because you have to wash it less often. A large part of garment wear and tear comes from the washing.The website mentions that the silver chloride is derived from recycled electronics. How environmentally friendly is that process? Where is it conducted?

To make it as environmentally friendly as possible we do all our manufacturing in Europe. We do the electronic recycling in Britain, to recycle the silver, and that is an absolutely closed process which means all the water goes back into the system to get as much silver out of the product as possible. Even when the people working in the plant wash their hands, all that water is also recycled to make sure that you get any silver out of it. From there, the silver is converted into a silver chloride emulsion, which is a concentrate that we ship to our distributers and from there to wherever in the world the Polygiene is applied to the fabric. We want to keep all the manufacturing in Europe for two reasons: one is for quality assurance, and the second is to ensure that we’re under the European legislation for chemical manufacturing.

Verdict:

My experience showed that the Polygiene does increase the amount of times I would wear a synthetic shirt before washing it. Typically I wash synthetics after one or two periods of intense physical activity, and the Polygiene shirts could usually wait for 2 to 3 uses, although once one of my items became stinky no amount of airing out would alleviate the smell.

Personally, the big test was to try the Polygiene products against merino wool, which is also known for its natural anti-odor properties. In terms of smell, I have found merino to perform better, as I can go on extended backpacking trips with only one or two shirts and no deodorant without complaints from my companions. In comparison, I went on a long day-hike wearing one of the half-zips from Polygiene and even after hanging it outside for two days afterwards there was no socially acceptable way of wearing it again before washing. That being said, synthetics can be preferable because they can minimize the appearance of sweat on the fabric, dry slightly faster, and are available in white (the bleaching process is too detrimental to the merino fibres for manufacturers to produce a bright, crisp, white).

Another reviewer’s experience of Polygiene treated garments was more favourable. The Polygiene treatment in the synthetic shirts allowed him to use them for 2 to 4 work-outs compared to a single use for the other synthetics he wears. While the shirts smelled as though they had been worn previously, they had no unpleasant odour.

Where the Polygiene shines brightest is in physical equipment which is generally washed less frequently than clothing. Brad tested mountain biking guards and issued a glowing praise of how much the Polygiene improved the smell of the equipment after multiple uses. If you’re looking to replace your own foul-smelling protective gear, this could be an attractive option!

|

PROS:

|

|

CONS:

|

SPECS:

Depends upon the individual products.

RATING: 9/10

| Effectiveness | 1.5/2 |

| Comfort | 2/2 |

| Innovation | 2/2 |

| Durability | 1.5/2 |

| Quality/Price | 2/2 |

Did we miss something? Are we totally out to lunch? Let us know what you think. People like/dislike gear for different reasons so chime in below and we'll get a well-rounded evaluation.

Leave a Comment:

Copyright © 2023-24 Backcountry Skiing Canada. All Rights Reserved.